AuxilIary elements

Auxiliary equipment control

The auxiliary equipment control is an integral part of the system MOREVIA in order to provide all processes control. A large variety of controlling and controlled equipment is available.

The control is fulfilled by local controllers integrated in one network. This solution provides the efficient process control even in a case of connection loss with other controllers. It is also possible to use local operator panels for local equipment management.

MOREVIA control system application:

- Pump control including automatic Start/Stop function. Frequency converter control and soft-start devices control.

- Valve control. Start/Stop and soft-start options are possible.

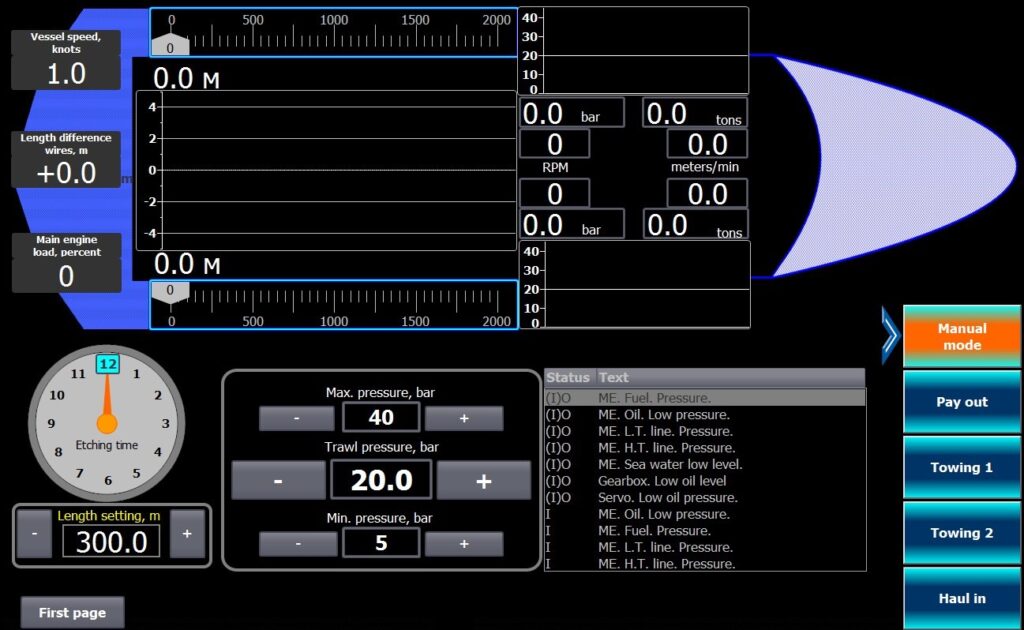

- Trawl control

- PID-controllers

- Compressor control

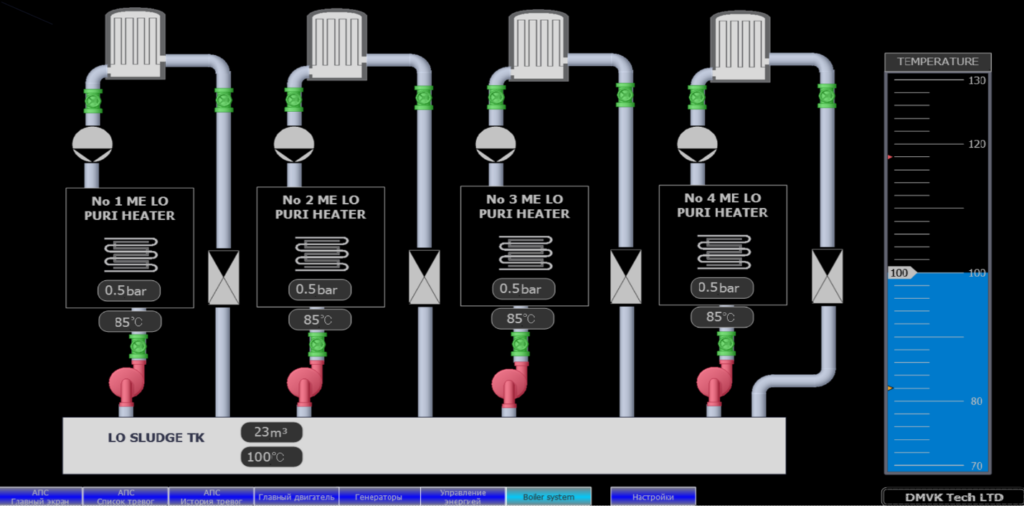

- Boiler control

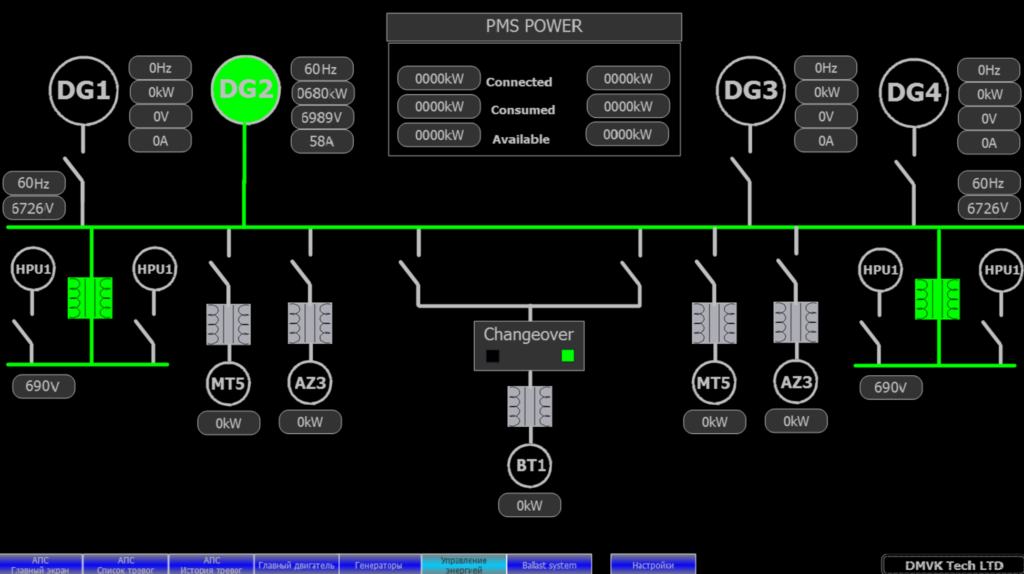

- Sequential Start/Stop, restart sequence after black-out

- Lubrication system control

- Heating and cooling system control

- Drinking water control

- Compressed air control

- Bilge control

- Fuel system control

- Ventilation control

Ballast Control

Remote monitoring and control

The ballast control system is an integral part of MOREVIA system, and provides remote monitoring and control of pumps and valves from the bridge, Central Control Room or other place. The system state is displayed in graphic pictures on the Operator panels or monitors. One-touch control provides easy and fast control.

The main functions:

- Level gauging in tanks.

- Pump control.

- Valve control.

- Ballast control.

- Heeling control.

- Control of pressure, temperature, flow counter, etc.

- Automatic functions

Tank Level Gauge

MOREVIA system can work with a large number of tank level gauging sensors, including hydrostatic, ultrasonic, microwave sensors. Additionally, there is an option of temperature, pressure and density measurement. The data is displayed in volume percent, centimeters, cubic meters. Constant monitoring of tank filling and emptying is provided. By using the integrated system, it is possible to connect tank filling level with the operation of additional equipment (for instance, turn off the pump or close the valve).

Precision measurement modules (14bit, of 16bits, if necessary) are always applied for level gauge. This guarantees that MOREVIA system does not make any measurement errors to the sensor reading. Data bus connection is also possible.

Sensor reading errors depend on the applied measurement technology. For instance, by applying microwave radars 2-3mm measurement accuracy can be achieved.

Level gauge system can be integrated into the general alarm system to warn on alarm level limits or can have a stand-alone alarm system.

Talk to us

Have any questions? We are always open to talk about new projects, creative opportunities and how we can help you.